Description

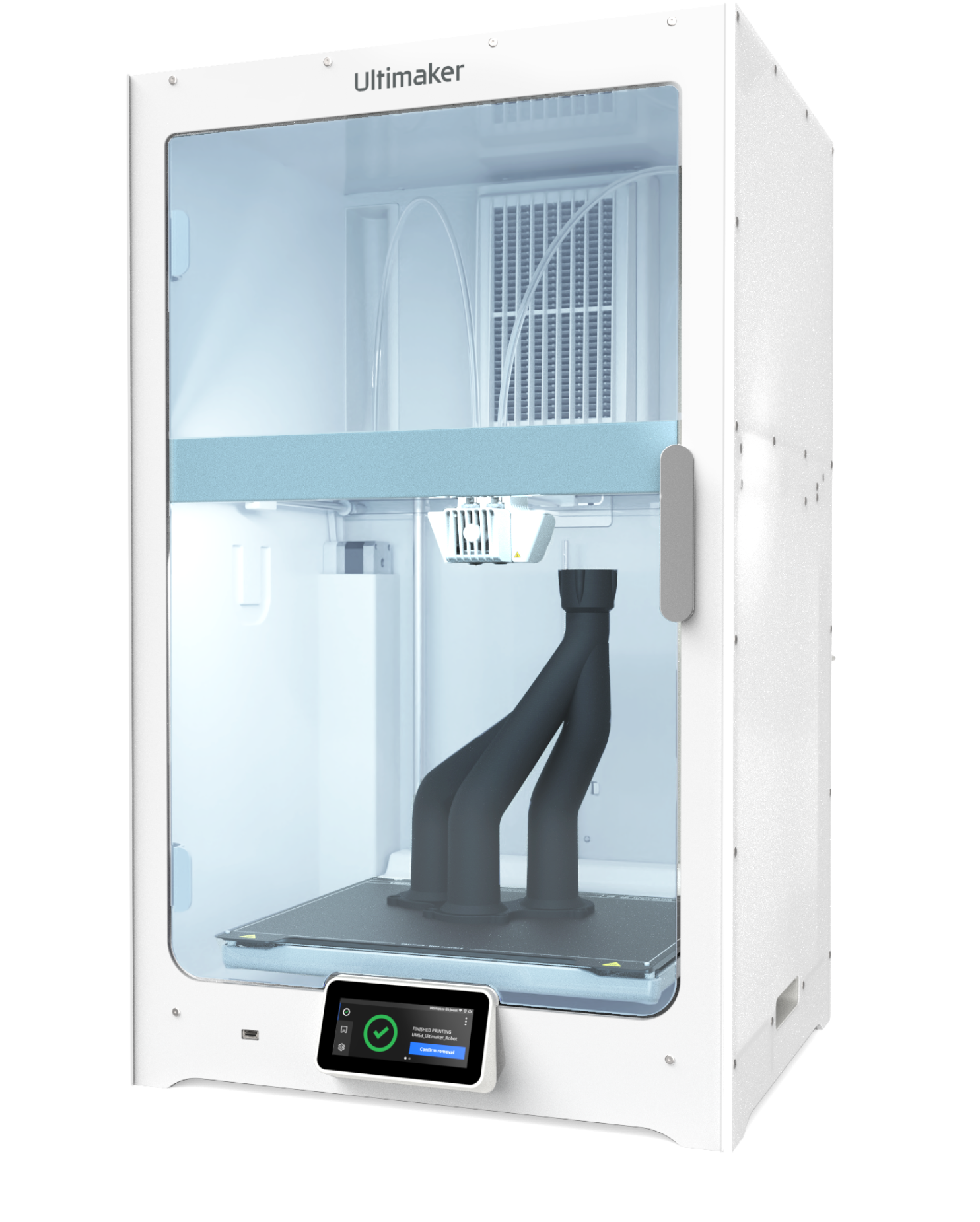

A new level of 3D printing success.

The UltiMaker S7 3D Printer produces high-quality parts and models more easily and reliably—from the first layer to the last—for an accessibly enhanced professional 3D printing experience.

Key Features of the UltiMaker S7 3D Printer:

- Integrated Air Manager

- Inductive Sensor Bed Leveling

- PEI Coated Flexible Build Plate

- High-Definition On-Board Camera

- Print Head Anti-Flood Sensor

- Bed Tilt Compensation

- 5 GHz Wi-Fi Compatibility

|

A new level of 3D printing success.We took everything our customers love about the award-winning UltiMaker S5… And made it even better. The S7 is packed full of our latest technology, making it easier than ever to 3D print high-quality parts. |

Set and forget. Out of the box.

Key features

| PEI-coated flexible build plate | Integrated Air Manager | More accurate inductive probing | Click and print with 280+ materials |

Easy printing.Easy breathing.Integrated Air Manager Not only does this increase air quality peace of mind… It also boosts print quality thanks to its fully enclosed build chamber and single glass door. |

|

Trusted by the world’s top designers and engineers

Introducing Ultimaker S7