Description

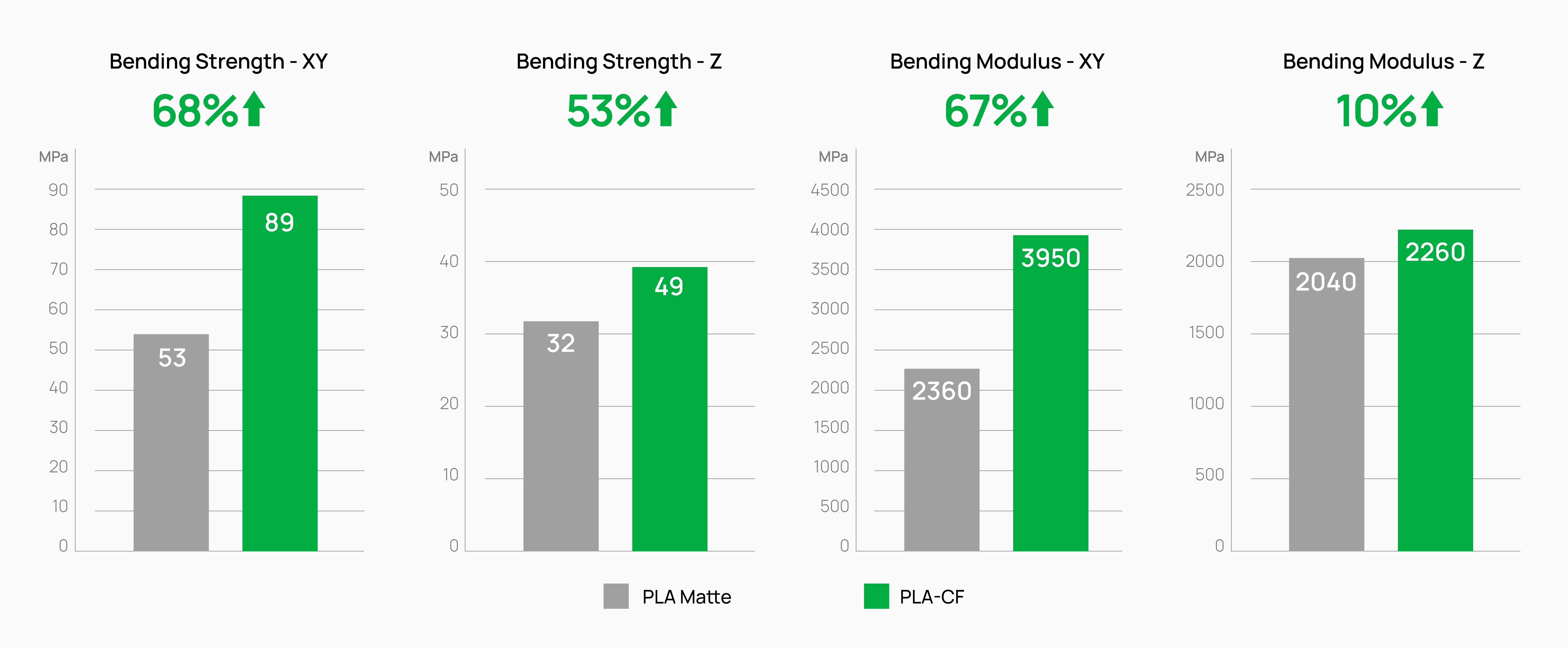

Bambu PLA-CF Filament Cyprus delivers the best of both worlds: the printability of standard PLA with the mechanical benefits of carbon fiber reinforcement. Designed for both functional and aesthetic applications, this filament offers outstanding stiffness, dimensional stability, and a smooth, professional finish.

High Stiffness for Functional Parts

With a stiffness rating of 3950 MPa, PLA-CF is built for parts that resist bending. Ideal for functional components, load-bearing applications, and mechanical assemblies.

**For optimal performance, orient your print to avoid stress on layer lines — the XY axis offers maximum strength.

Precision and Dimensional Accuracy

Low shrinkage and excellent warping resistance ensure that your prints match your design perfectly. This makes PLA-CF a reliable choice for assembly parts, scaling prototypes, and precision-fit models.

Ultra-Smooth, Layer-Free Finish

Carbon fiber helps conceal visible layer lines, giving your prints a refined, matte-like finish. Depending on your design, PLA-CF can replicate premium textures like fabric, clay, or soft matte surfaces.

AMS-Compatible for Simplified Printing

Bambu PLA-CF integrates RFID technology for instant printer recognition and parameter setup when used with the Bambu AMS system — just load and print.

Printing Tips

Printing Tips

1. Dry before use to ensure the best print quality and consistent finish. Drying conditions: In a blast drying oven: 50°C for 8 hours; In an AMS 2 Pro and AMS HT: 55°C, 8 hours; On an X1 printer’s heatbed: 60°C to 70°C for 12 hours. Store in a dry environment after use. For more details, please refer to: Filament drying instructions on WIKI.

2. The refill filament needs to be used with a spool. For detailed instructions on how to swap in the new filament using the Bambu Reusable Spool, please refer to the guide on WIKI.

-

Dry Before Use:

-

Blast drying oven: 50°C for 8 hours

-

AMS 2 Pro / AMS HT: 55°C for 8 hours

-

X1 printer’s heatbed: 60°C–70°C for 12 hours

-

Store in a dry environment after use.

-

-

Use Hardened Steel Nozzle:

-

0.4mm, 0.6mm, or 0.8mm hardened steel nozzle is required for carbon fiber filaments.

-

Stainless steel nozzles are not recommended.

-

-

Build Plate Recommendations:

-

Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate, or 3D Effect Plate.

- Use of Magigoo Glue

-

-

Optimizing Strength:

-

Align parts to minimize load on Z-axis layer lines.

-

Use higher infill for load-bearing parts.

Accessory Compatibility

Recommended Not Recommended AMS Series All / Build Plate Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate, 3D Effect Plate / Hotend Hotend with Hardened Steel Nozzle 0.4 mm / 0.6 mm / 0.8 mm Hotend with Stainless Steel Nozzle All Size

-

Frequently Asked Questions

Q: Is PLA-CF more difficult to print than standard PLA?

A: Not significantly. In fact, it retains PLA’s easy printability; however, it does require a hardened steel nozzle to prevent wear from the carbon fibers. Therefore, as long as you use the correct nozzle, printing PLA-CF is just as straightforward as standard PLA.

Q: Can PLA-CF be used for outdoor applications?

A: While it is stronger than regular PLA and can handle more demanding parts, it is not UV-resistant like ASA-CF. Therefore, for prolonged outdoor exposure, ASA-CF is the better choice. In addition, ASA-CF provides improved weather resistance and color stability.

Q: Does it require an enclosure?

A: No, PLA-CF does not require a heated enclosure. However, maintaining consistent printing conditions will improve surface quality and dimensional accuracy. As a result, using a draft shield or printing in a stable environment is recommended.

Q: Is it compatible with the AMS system?

A: Yes — RFID printing parameters are preloaded for plug-and-play operation.