Description

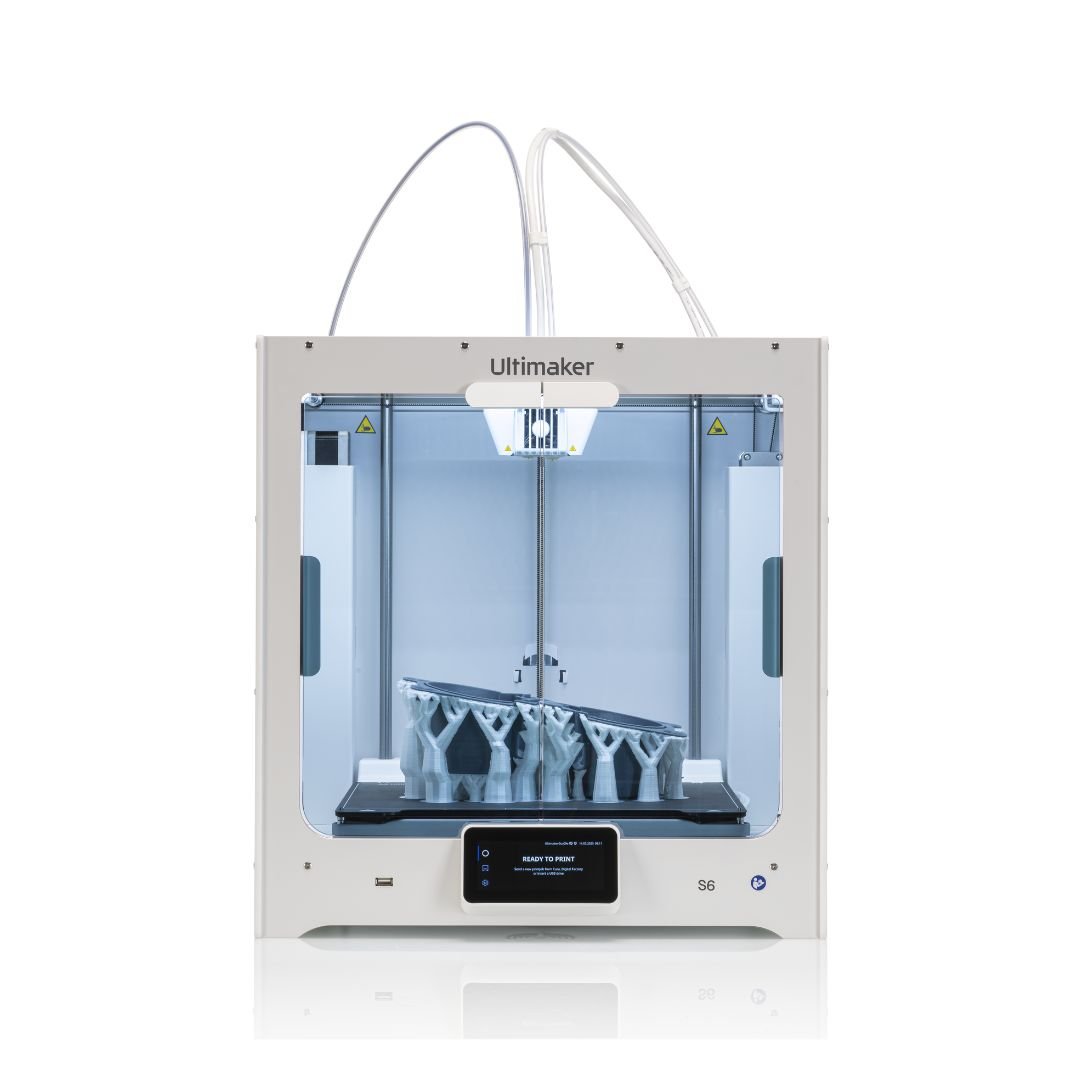

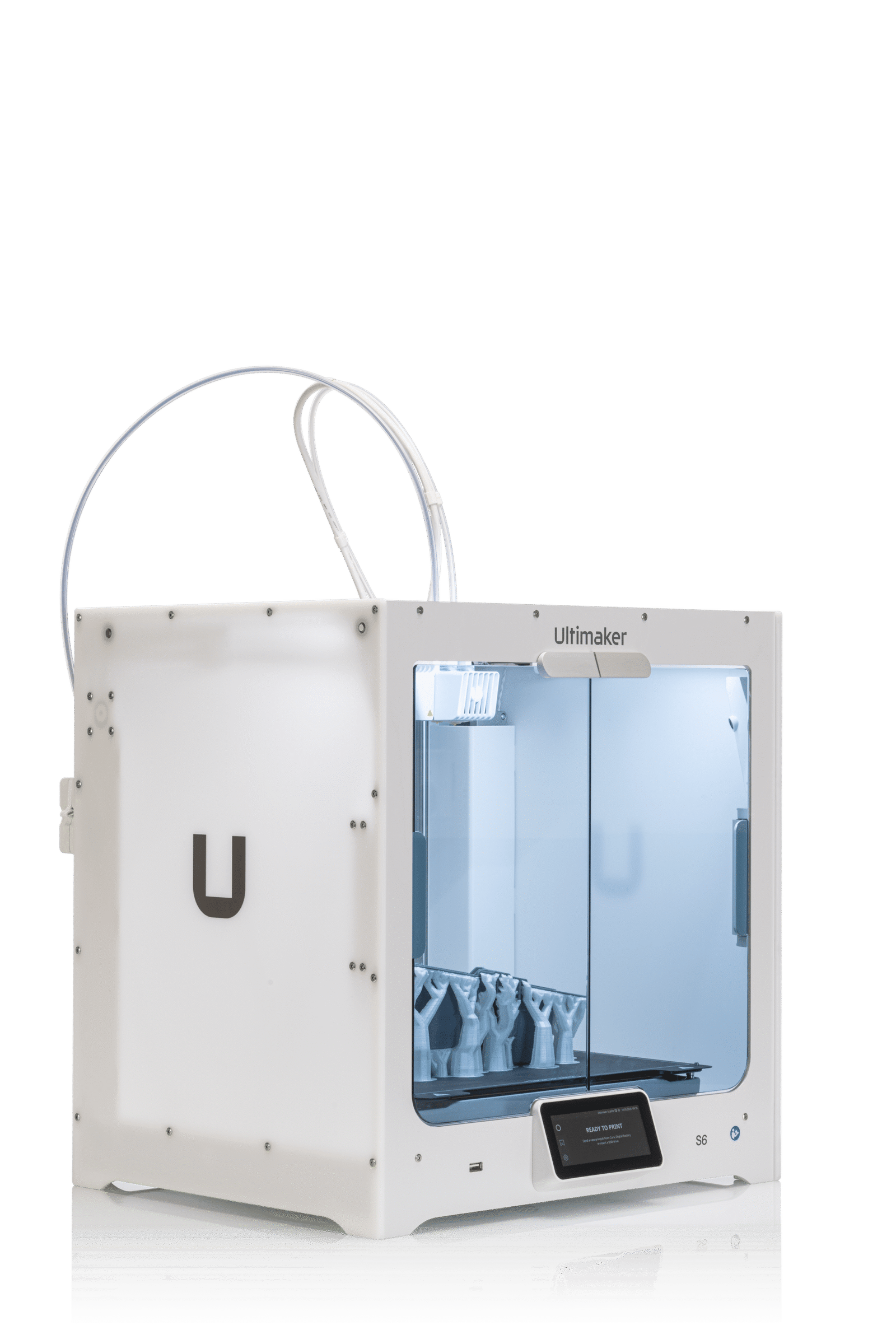

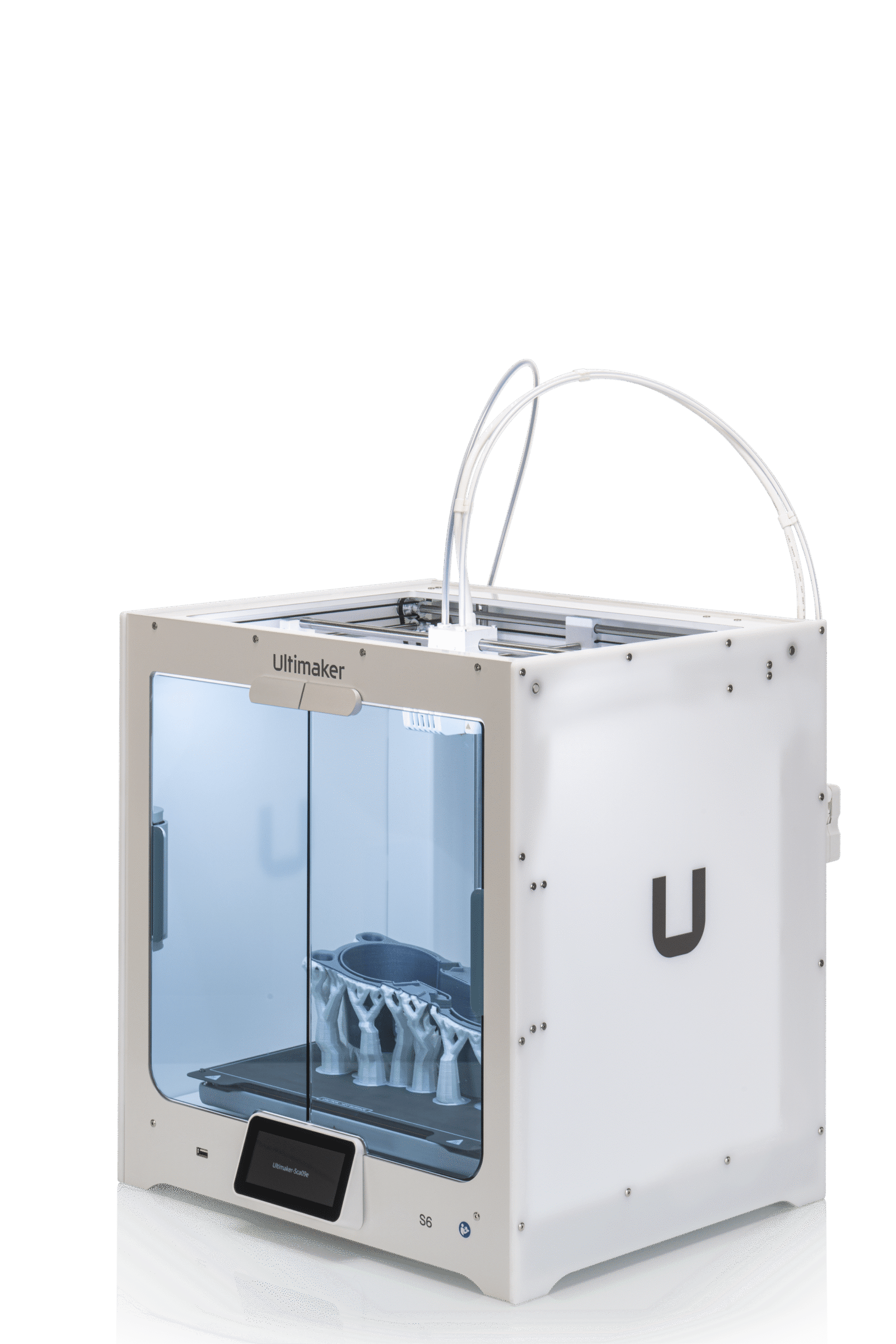

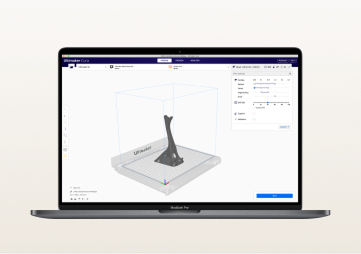

Ultimaker S6 3D Printer

The Ultimaker S6 is a next-generation 3D printer that builds on the reliability of the S5 while offering up to four times the productivity. Featuring an enhanced motion system, improved bed levelling, and choice of the build plate, the S6 delivers faster, smarter, and more flexible printing for professional users in Cyprus.

|

Key Features |

|||

| Composite-ready dual extrusion | 330 x 240 x 300 mm build volume | Award-winning touchscreen UI | Click and print with the most advanced materials |

Key Features

- Cheetah motion planner for higher speed and precision

- 330 × 240 × 300 mm build volume

- Dual extrusion for multi-material and support printing

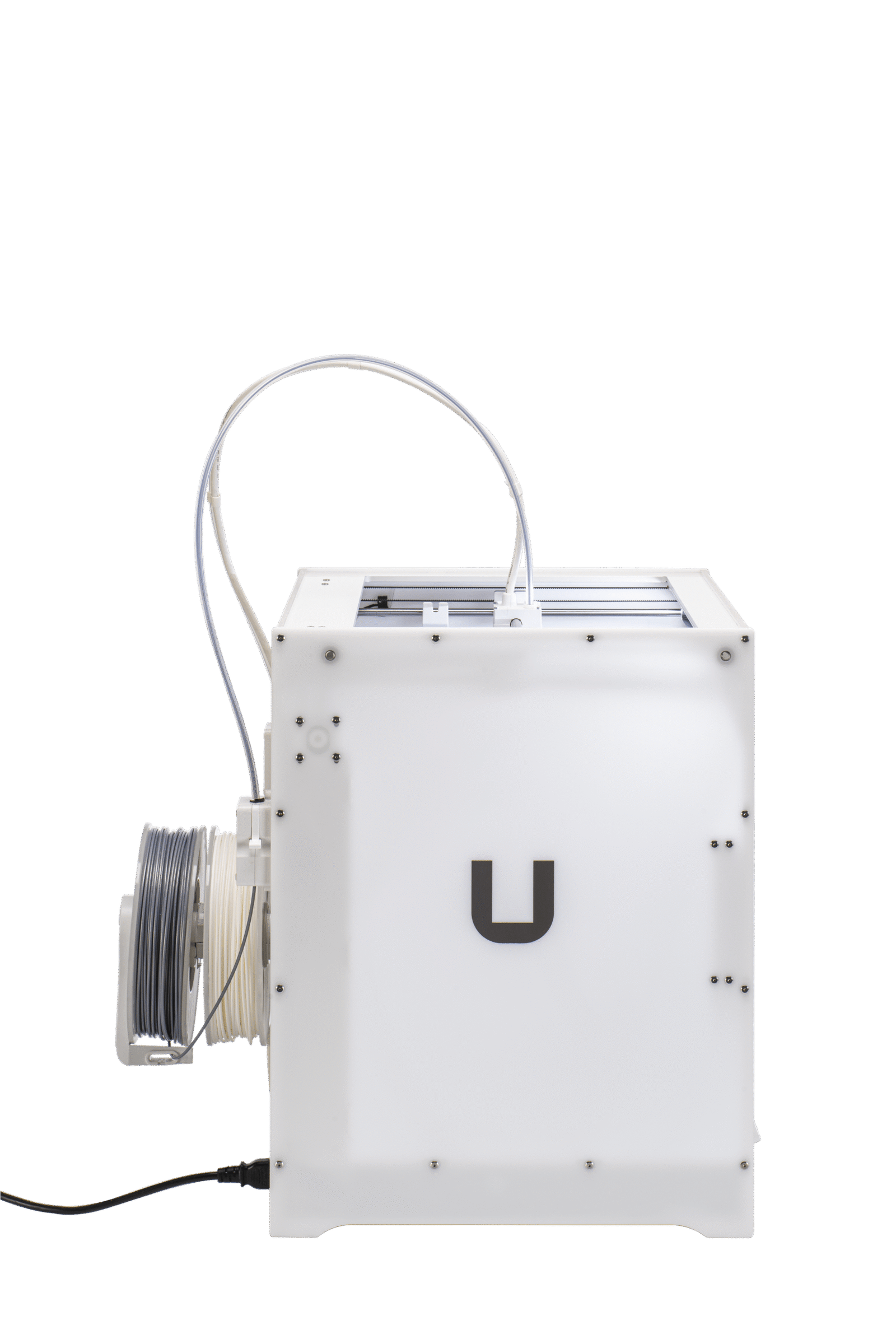

- Choose between Glass Plate and Flex Plate

- Integrated with UltiMaker Cura and Digital Factory

- Touchscreen interface with guided workflows

Speed and Accuracy with Cheetah Motion Planner

The advanced Cheetah motion planner enables travel speeds up to 500 mm/s and acceleration up to 50,000 mm/s². As a result, you can complete complex print jobs up to four times faster than with the S5. Moreover, it achieves this without compromising precision or reliability, making it ideal for high-throughput environments.

Advanced Dual-Extrusion for Material Flexibility

With auto-nozzle lifting and support for composite and engineering materials, the S6 handles dual-extrusion prints with ease. For example, you can print strong functional parts while using soluble support materials. Furthermore, its compatibility with a wide range of filaments ensures top-tier performance and adaptability.

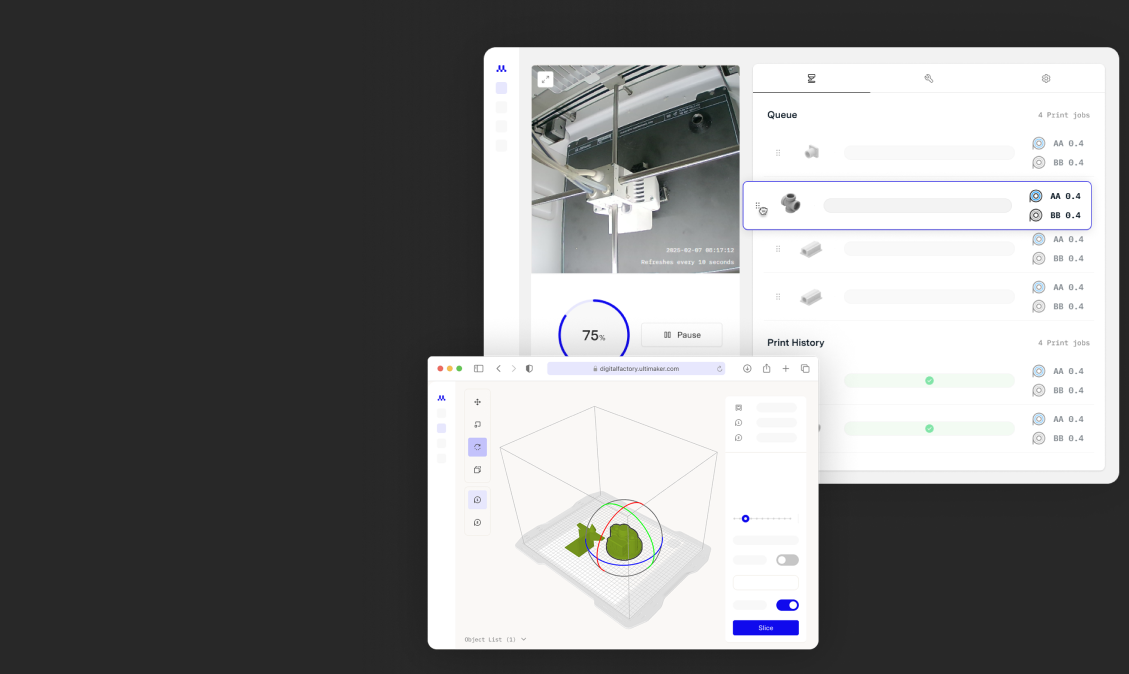

Integrated Software and Workflow Automation

The S6 fully integrates with UltiMaker Cura and the Digital Factory. Thanks to automated filament recognition and inductive bed leveling, setup time is reduced significantly. In addition, remote print queue management becomes effortless with real-time monitoring and cloud sync, streamlining your workflow from start to finish.

Connectivity and Remote Control

Stay connected with Wi-Fi, Ethernet, and cloud options. Consequently, you can manage jobs remotely and view print progress through the built-in HD camera. This level of connectivity is ideal for distributed teams or production environments across Cyprus and beyond.

|

|

|

| High flow print cores

The new AA+ and CC+ print cores, exclusive to the UltiMaker S6, have a new quad-chamber design. Allowing for 2.5x more flow and also help regulate the pressure in the print head for cleaner prints.

|

Backwards compatible with the Material Station

Designed to be left unattended, the Material Station allows the UltiMaker S6 to 3D print longer – day or night. Loading material into the Material Station takes seconds – not minutes.

|

Cura integration

Access the UltiMaker Cura features that speed up your workflow and increase print success – like intent profiles, easy remote printing, and more.

|

Frequently Asked Questions

What materials does the S6 support?

It supports over 300 filaments including PLA, PVA, CPE+, PC, Nylon, PP, and composites.

Does it auto-level the bed?

Yes. Inductive sensors and active leveling ensure a perfect first layer, every time. This makes setup much easier and improves first-layer success rates.

Can I use it remotely?

Absolutely. With Digital Factory and built-in camera support, you can manage everything from your browser. As a result, you can monitor multiple printers across locations.

Is this suitable for Cyprus-based businesses?

Yes. Thanks to its robust network options, localized support, and professional-grade performance, it fits well in Cypriot companies, schools, and workshops.

Learn More

Visit the Ultimaker S6 product page for complete technical specifications.

Explore UltiMaker’s ecosystem via Ultimaker Cura and Ultimaker Cloud.